The crash behavior of relevant components does not only depend on design geometry and material properties, but is also influenced by manufacturing history. A failure can be caused by local thickness reduction or residual stress peaks which are a result of the stamping process. This failure can limit the functionality of the entire component. In particular, the local hardening step can induce gradients in the phase proportions or influence residual stresses – and thus influence the dynamic behavior of the crash part.

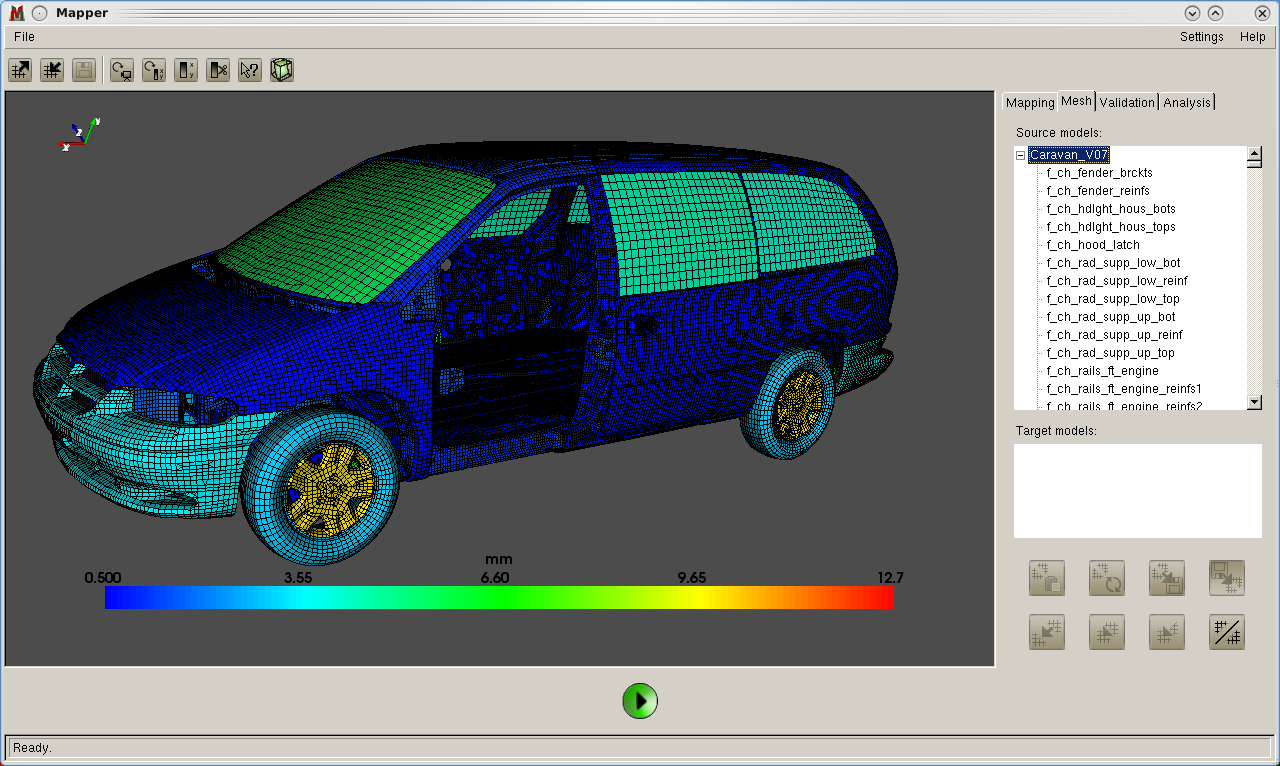

MpCCI Mapper allows to check the geometric compliance of two models by calculating the local distances between them. The (automatic) mesh alignment helps to adjust the positions of two models if they are not in a non-conformal coordinate system. A robust mapping algorithm enables the transfer of various physical quantities (with nodal-, element- or shell-layer based locations) for all standard shell element and mesh types. The mapping works for different integration types as well as for different number of integration points in thickness direction for source and target model.

By using a so-called »back-mapping validation« the user can check and estimate the influence of locally incompatible mesh discretizations on the mapping quality. In a similar way, the user may compare experimental data (e.g. from forming analysis tools like Atos, Argus, or Autogrid) with simulation results. The MpCCI Mapper can provide local quantity difference images, which then can be used to adjust the parameters of the forming simulation.